Factory Price 395nm Wavelength Focused 3000W UV LED Curing Light

Professional UV LED curing system with adjustable stand for precision bonding of acrylic glass and shadowless glue applications.

Technical Specifications

| Catalogue number | MF-GHUV-300W |

| Duration Time | N/A |

| Version | Manual |

| Colour | Grey/White |

| Output | LED 300w |

| Light Source | 35-360PCS |

| Active power | 300W |

| Power supply | 85-265 V AC 50/60Hz |

| Dimming mode | NO |

| Temperature range | -10 to +45°C |

| Material | PC+Aluminum |

| IP Rating | IP43 |

| Housing Warranty | 36 Months |

| LED lifetime | 50,000 work hours |

Product Features

- Europe and United States hot models

- CB CE certification

- Patented products

- Customization available

- Whole picture printing laser engraving

- Multiple mounting options: hanging/wall hanging/ceiling hanging/side hanging

- Customized patterns

- 395NM/365NM/405NM wavelength options

- Customized LOGO for small orders

Key Performance Features

- Ultra-Fast Curing: 3535-chip LEDs achieve curing in 1-3 seconds, boosting production efficiency

- Dual-Fan Cooling: High-speed fans with aluminum housing ensure optimal heat dissipation

- Multi-Wavelength: 365NM (electronics), 395NM (acrylic bonding), 405NM (3D printing resin)

- Industrial Durability: Die-cast aluminum body with anti-drop and anti-shock properties

- Flexible Mounting: Adjustable stand and handheld design for versatile applications

- Global Voltage: AC100~265V input compatible with international power standards

Product Advantages

- Energy Saving: 60W~300W options with 50% lower energy consumption than traditional lamps

- Long Lifespan: 50,000-hour LED lifespan with 36-month housing warranty

- Precision Wavelength: Mirror reflector concentrates UV energy for consistent output

- Plug-and-Play: Instant full-power operation, no warm-up time required

- Customization: Laser engraving and LOGO printing available for branding

Detailed Product Photos

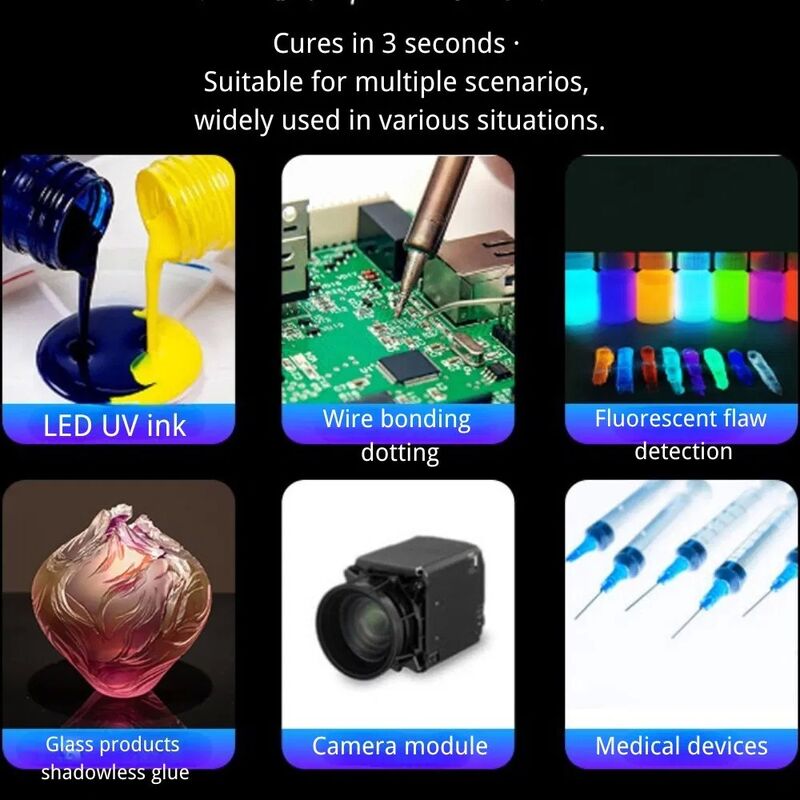

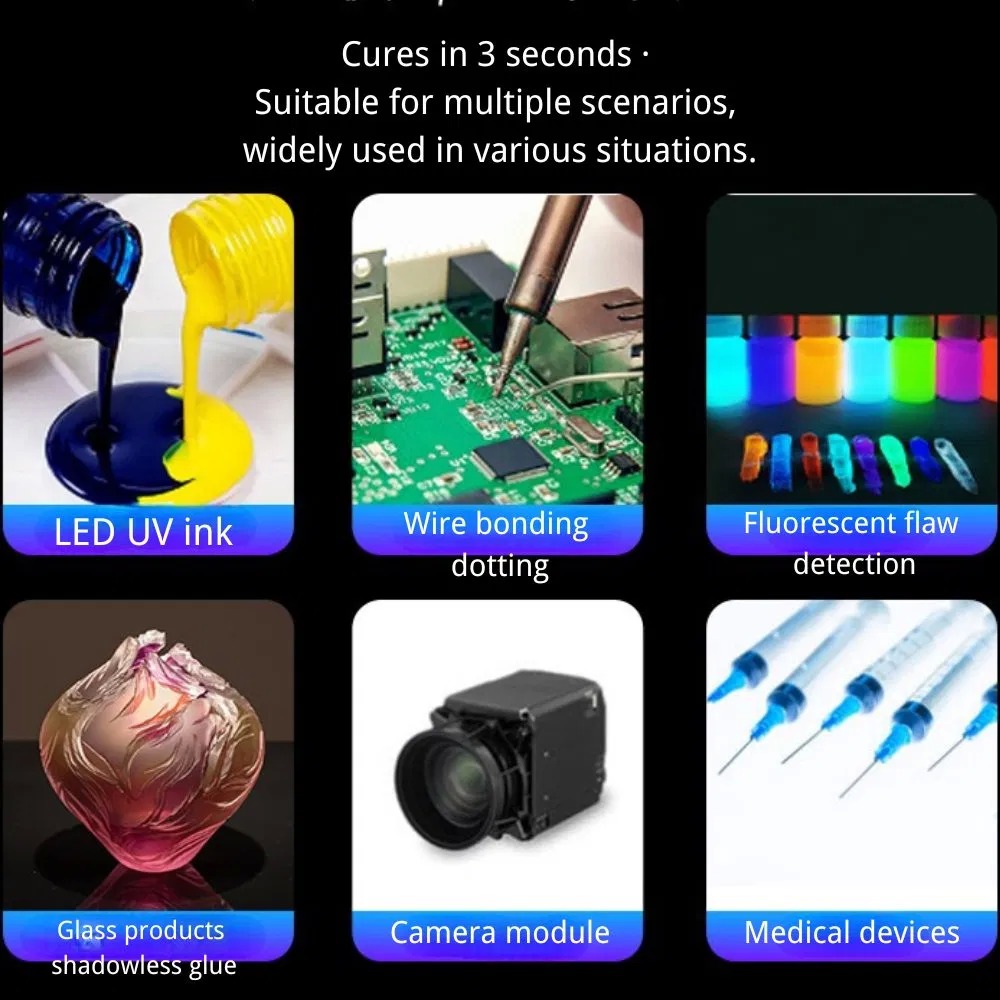

Industrial Applications

- Electronics Manufacturing: Curing UV glue for smartphone screens and camera modules

- Automotive Industry: Fast-curing navigation screen coatings and interior UV paints

- 3D Printing: 405NM wavelength ensures smooth resin curing for rapid prototyping

- Construction: UV coatings for wall panels and tiles enhance durability and aesthetics

- Medical Devices: Sterile bonding and fluorescent agent detection

- Printing & Packaging: Instant drying of UV inks for premium packaging

Technology Advantages

As a new generation UV curing light source, UVLED technology offers significant advantages in energy conservation and environmental protection while maintaining low production and operational costs. The system provides precise power control, adapts to various user environments, and features convenient adjustability, compact size, and customizable light source shapes for diverse industrial applications.

UVLED curing systems cover numerous industrial assembly applications including PCB, LCD, electronics, plastics, footwear, glass, building material coating, handicraft glazing, printing plate making, ink drying, medical physiotherapy, aging experiments, optical catalysis, optical repair, fluorescence analysis, and fluorescent flaw detection.

Common applications include mobile phone screen curing, glass shadowless glue curing, furniture surface coating curing, tile/building material surface color curing, floor color applications, and clothing textile digital inkjet printing.

Wavelength Function: Short wavelengths work on surface applications while long wavelengths penetrate deep layers of inks or coatings.

Building Material Coating Applications

Primarily used for instant curing of large-area surface paints, coatings, adhesives, and inks through the advantageous characteristics of UV curing lamps. This process imparts gorgeous surface gloss, weather resistance, abrasion resistance, water resistance, acid and alkali resistance, and other high-strength curing protections to panels and surfaces.

Widely applied to flat coatings for integrated wall panels, ceramic tiles, glass, furniture panels, wallboards, and composite panels. Common UVLED curing lamp solutions typically measure around 1000mm in length.

Packaging & Shipping

Frequently Asked Questions

Q1: Are you a factory or a trading company? Where is your company located?

A1: We are 100% a factory, not a trading company. Our company is located in Dongguan, between Shenzhen and Hongkong Guangzhou, China.

Q2. How about the lead time of LED Linear High Bay Light?

A2: 3-7 days for sample order, 15-25 days for mass production order based on order quantities.

Q3. Can I have a sample order for LED Tri-proof Light?

A3: Yes, sample order to test and check quality is welcomed. Mixed samples are acceptable.

Q4: How do you ship the finished production?

A4: By SEA, AIR or Express (DHL, UPS, Fedex, TNT, etc) are optional.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!