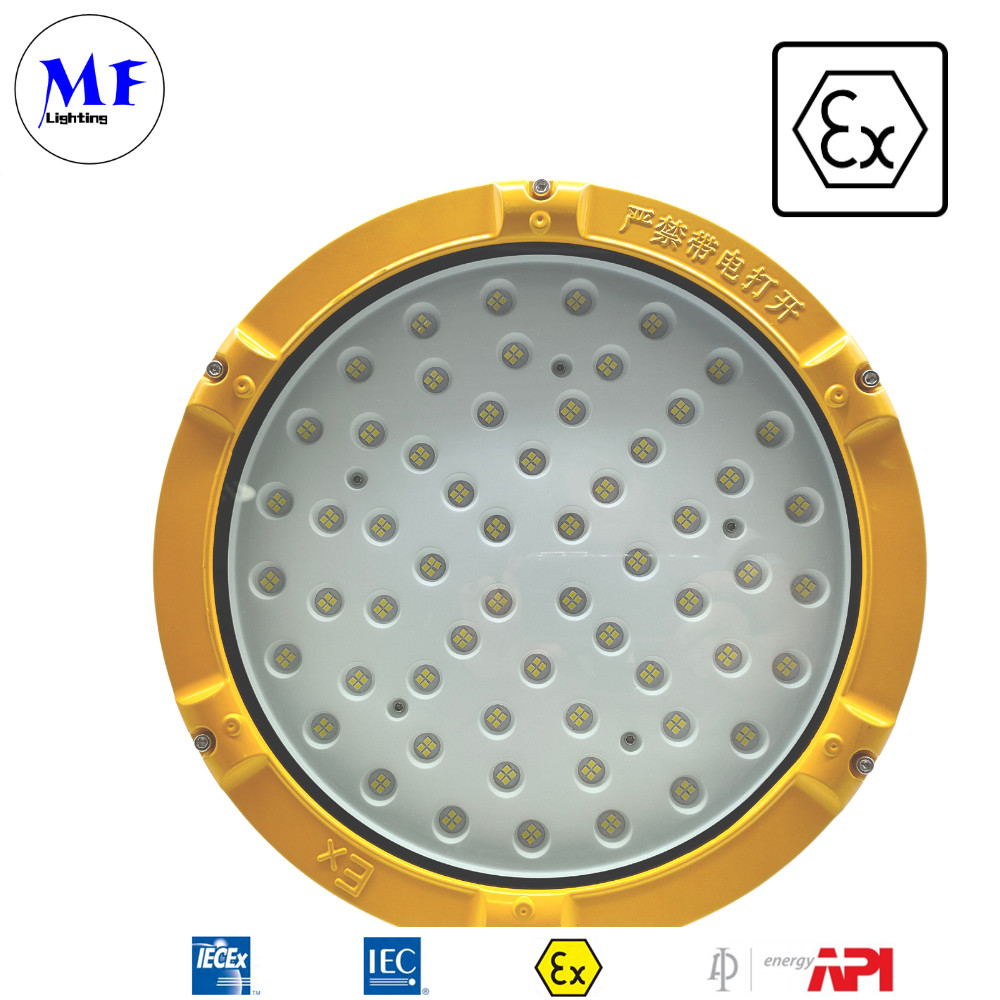

Product Description

>FEATURES

• Working Temperature: -40°C ~ +60°C.

• High quality SMT LED and Meanwell Driver.

• Light-weight design by aluminum.

• Heavy-duty and high impact resistance.

• Round low bay lighting with motion sensor.

• Unique design enhance airflow for greater heat dissipation.

• Field installation in a few minutes.

• Isolated LED compartment reduce temperature within LED driver housing.

>SPECIFICATION

| Model |

Wattage |

Color Temperature |

Voltage |

Lumens |

Warranty |

CRI |

| EX-50W Q1YZDA |

50 |

2200K-7000K |

AC100-277/220-480V |

7000 |

5 years |

80 |

| EX-100W Q1YZDA |

100 |

14000 |

| EX-150W Q1YZDA |

150 |

21000 |

| EX-200W Q1YZDA |

200 |

28000 |

| EX-300W Q1YZDA |

300 |

42000 |

"F3,F4 "=Product code. "Y"=D or N D:Dimmable or N: non-dimmable "Z"=CCT, from 2200-7000k, 22 for 2200k...70 for 7000K. "D"=Beam angle, D40 for 40°, D60 for 60°, D90 for 90°, D120 for 120° "A"=glass type. blank for flat glass, C for spherical glass.

>EXPLOSION PROTECTION

Marking Atex

II 2 G Ex nr IIC T6 GC

Il 2 D Ex tb IIIC T80 Db Ip66

Marking IECEX

Ex nr IIC T6 GC

Ex tb IIIC T80 Db Ip66

Other Rating

IP 66

>MATERIALS

• Housing: Aluminum

• Lens: Tempered Glass

• Mounting Bracket: Aluminum/SUS 304

>ACCESSORIES

Explosion-proof lights are designed to be used in environments where flammable gases, vapors, or dust particles are present. These lights are built to prevent ignition of the surrounding hazardous atmosphere, ensuring the safety of the workers and the facility. Here are some common applications of explosion-proof lights:

Oil and Gas Industry:

Explosion-proof lights are extensively used in oil refineries, drilling rigs, offshore platforms, and petrochemical plants. These facilities often have areas where flammable gases or vapors are present, making it necessary to use explosion-proof lighting fixtures.

Chemical Plants:

Chemical processing plants deal with volatile substances that can pose a significant explosion risk. Explosion-proof lights are utilized in various areas such as storage facilities, production areas, and laboratories to provide safe illumination.

Mining Operations:

Mines are prone to the accumulation of combustible gases and dust, which makes explosion-proof lighting crucial for worker safety. Underground mines, coal mines, and other mining environments require specialized lighting fixtures that can withstand hazardous conditions.

Manufacturing Facilities:

Certain manufacturing processes involve the use of flammable materials or generate combustible dust. Explosion-proof lighting is employed in these facilities to minimize the risk of explosions and ensure visibility for workers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!